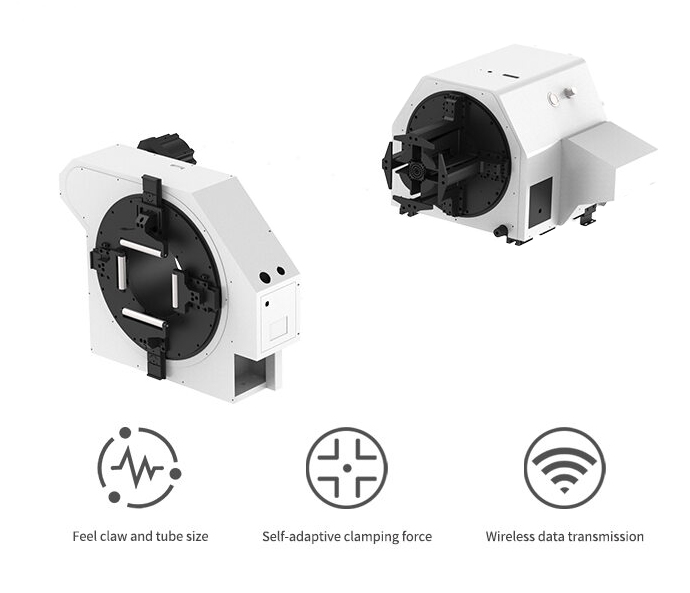

Make Good for Deficiency

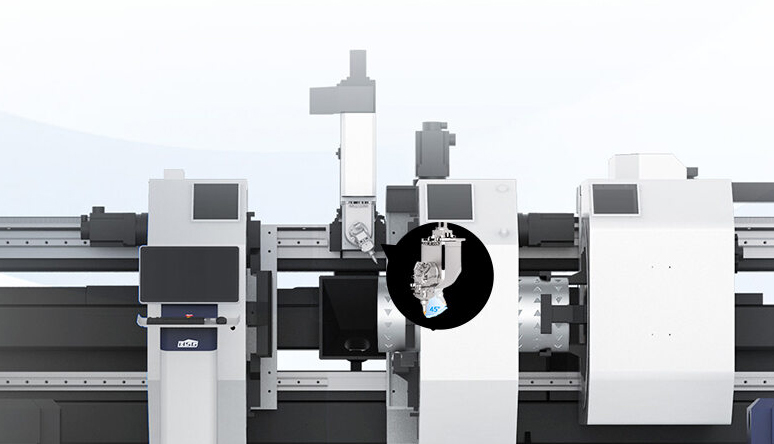

Our self-developed intelligent digital chucks gather up advantages of hydraulic (large clamping force and stable cutting for heavy materials) and pneumatic chuck (high clamping accuracy) and cover the shortage of them, namely, high energy consumption & easy to damage. With digital signal, the chucks can match with proper air pressure, adjust clamping force automatically and offer wireless data transmission. Due to closed-loop control, they are safe and reliable for users.

Wide Range of Clamping, Easy to Operate

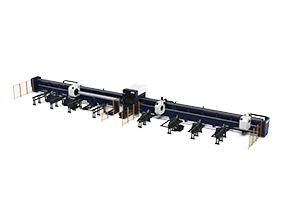

The digital chucks are capable of feeling claw status and tube size and changing clamping force in self-adaptive way, which will not only clamp conventional tubes like round and square tube, but also easily process profiles incl. channel and angle steel as well as special-shaped tubes, such as, drop-shaped, C- and L-shaped tubes. Tiny tubes (Φ10mm) will remain unchanged and oversized (Φ426mm), extra-heavy (1.5t) and overlong tubes (12000mm) are clamped steadily.

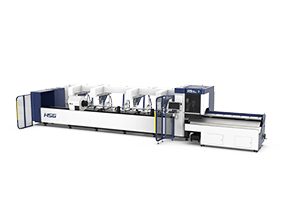

Real “0” Tailing, Reduction in Raw Materials, Boost Core Competitiveness

With four-chuck reversing cutting and various clamping modes, tubes are cut with zero tailing, in this way, improving material utilization to 100% and saving production costs; In combination with our developed tube cutting system and 3D five-axis bevel cutting technology, it is easy to cut 45° bevel and splice tubes together seamlessly. With this, users can expand their scope of service, accept more diversified orders and boost competitiveness among peers.

Applicable models